6. Quality Control in Kombucha Brewing: How We Ensure Consistency and Excellence

Behind every bottle of kombucha lies a complex process of fermentation that requires strict attention to detail. From selecting the right tea to testing pH and carbonation levels, every step is essential to producing a consistent, high-quality product that tastes great and is safe to drink.

In this post, we’ll walk you through the rigorous quality control measures that go into every batch of kombucha—from raw ingredient inspection to bottling, testing, and shelf-life assessments. These steps ensure that the kombucha you enjoy is of the highest standard, every time.

Selecting and Inspecting Raw Ingredients

The foundation of any great kombucha starts with the raw ingredients. To ensure quality, both the tea and sugar are carefully selected and inspected upon arrival at the brewery.

-

Tea Choice: Whether it’s black, green, white, or herbal tea, the type of tea used can influence the flavour profile and fermentation process. High-quality tea is crucial for achieving the right balance of flavour and health benefits.

-

Sugar: Sugar is the primary food source for the SCOBY (Symbiotic Culture of Bacteria and Yeast) during fermentation. We use white granulated sugar, to provide the right conditions for fermentation. Upon arrival, both the tea and sugar are tested for quality, ensuring no contaminants or inconsistencies will affect the brew.

Creating a Sterile Work Environment

A sterile work environment is key to avoiding contamination by unwanted microorganisms, which can spoil the batch or cause irregular fermentation. We have a dedicated Fermentation Room which is sealed off with extractor fans and air filters. Before entering, we wear lab coats, hairnets, gloves, and remove outdoor footwear to avoid any contamination. The room is regularly deep cleaned and sanitised to prevent the growth of any harmful bacteria or mould.

Precise Brewing and Steeping Process

Consistency is essential when it comes to brewing kombucha. Every batch must follow precise instructions to ensure the right balance of flavour and fermentation.

-

Brew Time and Temperature: The tea is steeped for a specific time at a controlled temperature. This step extracts the optimal flavours from the tea while preparing it for fermentation.

-

Recipe Sheet: Every batch follows a carefully crafted recipe sheet that outlines the exact brewing time, temperature, and tea-to-water ratio. By sticking to this formula, we ensure consistency across all batches.

Testing the Starter Liquid: pH, Brix, and ABV

Before adding the starter liquid (the kombucha from a previous batch) to the freshly brewed tea, we test it to make sure it’s in the right condition for fermentation.

-

pH Testing: The pH of the starter liquid is checked to ensure it falls within the ideal range for fermentation. This acidic environment helps create the perfect conditions for the SCOBY to thrive.

-

Brix Measurement: Brix is a measure of the sugar concentration in the liquid. Testing the Brix ensures that the sugar content is optimal for fermentation and will provide the right energy for the yeast and bacteria to do their work.

-

ABV (Alcohol by Volume): Kombucha naturally ferments and produces small amounts of alcohol. By testing the ABV, we ensure that the alcohol content remains within limits (usually under 0.5%) and that fermentation is proceeding as expected.

Once the starter liquid passes these tests, we add it to the fresh brew, using the same percentage of starter liquid each time to maintain consistency in fermentation.

Monitoring Fermentation: pH, Brix, Temperature, and Taste

The fermentation process is where kombucha transforms from sweet tea into kombucha. During this phase, we perform regular tests to ensure that the kombucha is fermenting correctly and consistently.

-

pH and Brix Testing: Regularly measuring the pH and Brix helps us track the progress of fermentation. As fermentation occurs, the pH drops and the sugar content decreases. Monitoring these parameters ensures the kombucha is developing as it should.

-

Temperature: Fermentation thrives at a stable, warm temperature—usually between 24-26°C. By keeping the fermentation area within this range, we help ensure the yeast and bacteria cultures remain active and healthy.

-

Taste and Colour: Kombucha is regularly tasted throughout fermentation to assess its flavour profile. The colour is also monitored, as it can indicate the development of the kombucha and whether any adjustments are needed. The recipe sheet includes specific parameters for the ideal taste, colour, and carbonation level, allowing us to fine-tune the brew if necessary.

Bottling: Ensuring Consistency in Every Bottle

Once fermentation is complete, the kombucha is ready to be bottled. Bottling is a crucial step in the quality control process, as it’s where the kombucha is prepared for final consumption. We take great care to ensure each bottle is filled to the same standard:

-

Carbonation Level: Carbonation is a key feature of kombucha. We carefully monitor the carbonation level to achieve the desired fizziness. This ensures that every bottle has the same refreshing effervescence.

-

Fill Level: Bottles are filled to a consistent level to ensure they are properly sealed and have enough headspace for carbonation expansion.

-

Non-Sterile Filtration: Some kombucha producers filter their kombucha before bottling to remove yeast sediment. We use non-sterile filtration, which preserves the natural flavours and benefits, while giving the kombucha a clear appearance.

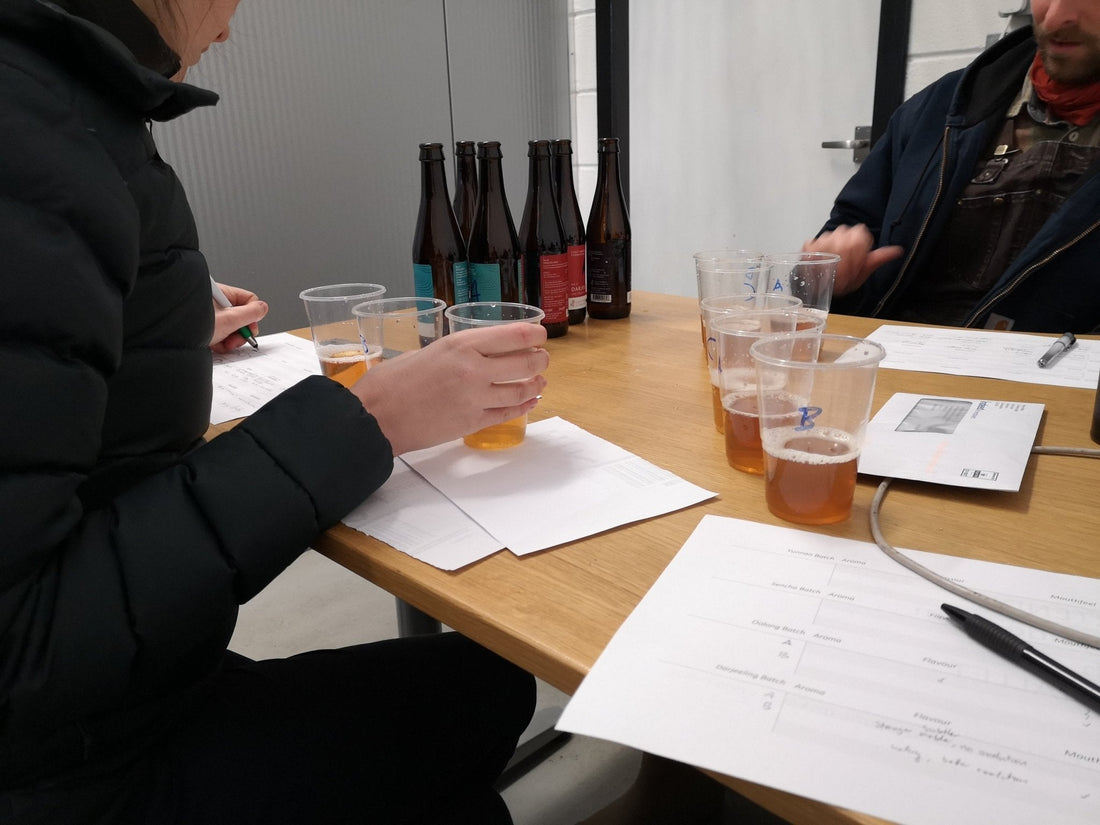

Pre-Sale Taste Testing and Flavour Evaluation

Before a batch of kombucha is released to the public, it undergoes a comprehensive tasting and quality control process.

-

Blind Flavour Chart Testing: The whole team participates in a blind tasting session, comparing the current batch against day 1 and previous batches. We use a standardised flavour chart to evaluate key factors like acidity, sweetness, and carbonation.

-

Standard Deviation: We calculate the standard deviation for each batch to determine how closely it aligns with previous batches. This helps identify any inconsistencies in flavour, aroma, or carbonation that might affect the final product.

-

Historic Taste Tests: We regularly taste kombucha from previous batches to track how the flavour develops and ages over time. This helps us maintain consistency and improve our recipes.

Shelf-Life Testing

Kombucha, like any food or beverage, has a shelf life. To ensure that our kombucha remains fresh, flavourful, and safe for consumption, we conduct thorough shelf-life testing.

-

Start and End of Life Testing: We monitor several factors at the beginning and end of the kombucha’s shelf life (typically 6 months). This includes testing the pH, Brix, ABV, appearance, aroma, and taste. We want to ensure that the kombucha maintains its quality and flavour over time.

External Lab Testing: Microbial and Pathogen Safety

To ensure that our kombucha is free from harmful pathogens, we periodically send samples for external lab testing. These tests check for microbial contamination, including any harmful bacteria or yeast that could compromise the safety of the product.

Producing high-quality kombucha is a labour of love, requiring attention to detail at every stage of the brewing and bottling process. From selecting the finest ingredients to performing rigorous testing and taste evaluations, we take great care to ensure that each bottle meets our strict quality standards. Whether you're a long-time kombucha enthusiast or a newcomer, you can trust that our kombucha is crafted with the utmost care and dedication to excellence. Cheers!